Your customer orders their favourite beer. It arrives looking dull, with barely a head, and goes flat within minutes. Compare that to a pint poured with a creamy, lasting foam, crisp carbonation, and full-bodied flavour. One leaves a customer disappointed; the other earns repeat business. The difference? It often comes down to what’s happening behind the bar.

Beer dispense equipment plays a crucial role in the final pour. It’s not just about getting the beer from keg to glass—it’s about preserving its quality every step of the way. From flavour and mouthfeel to foam retention and aroma, the right setup makes all the difference.

Yet, many issues with poor taste, inconsistent pours or excessive wastage stem from neglected or unsuitable equipment. Dirty lines, incorrect pressure, or impure gas can all spoil a pint before it even reaches the customer’s hand.

By the end of this guide, you’ll understand:

- How each part of a beer dispense system contributes to flavour, foam, and consistency

- The risks of using poor-quality CO₂ or unfiltered gas

- The impact of equipment setup on customer experience and waste

- How to maintain dispense systems for optimal performance

- Why gas purity is essential—and how Sure Purity’s filtration systems help protect quality behind the bar

Whether you run a brewery, bar, or event setup, understanding your equipment is essential to improving consistency and customer satisfaction.

Why Beer Dispense Equipment Quality Matters

Every pint poured is a reflection of your business. Whether you’re running a busy bar, a small taproom, or a brewery tap, what comes out of the tap directly shapes your customer’s impression. Poor beer quality doesn’t just disappoint—it damages brand reputation, increases waste, and drives customers elsewhere.

Flavour, Foam, and First Impressions

Beer is a delicate product. Its flavour profile, aroma, carbonation level, and visual appeal all rely on careful handling. The dispense system—made up of couplers, lines, gas cylinders, and taps—is the final link in the production chain. If this setup is flawed, even the best brew can be ruined at the point of serve.

Poor-quality or neglected equipment can lead to:

- Inconsistent pours, with varying carbonation and temperature

- Over-carbonated or flat beer, depending on pressure and gas settings

- Loss of foam head, which affects aroma and mouthfeel

- Poor lacing, which can suggest staleness or poor glass hygiene

- Increased wastage, both from overpouring and discarded beer

Customers expect consistency. If their pint tastes different from one visit to the next, they notice. In hospitality, quality equals trust—and trust builds loyalty.

The Cost of a Bad Pour

It only takes one bad pint to lose a regular customer. In a competitive market, every glass counts. Wasted beer, negative reviews, and complaints all eat into your margins and reputation.

But it’s not just about avoiding poor results. High-quality dispense equipment, when correctly maintained and paired with clean, filtered CO₂, helps:

- Preserve flavour integrity

- Maintain ideal carbonation

- Ensure long-lasting foam stability

- Reduce product and gas waste

- Deliver a consistent experience, pint after pint

This is where systems like Sure Purity’s Carboguard come in. Our polishing filters are designed to filter out impurities in the gas supply and ensure your dispense equipment performs at its best. It’s important to measure the purity of your co2 to make sure you have clean gas. This, coupled with quality equipment, and regular maintenance create the foundation for better beer and happier customers.

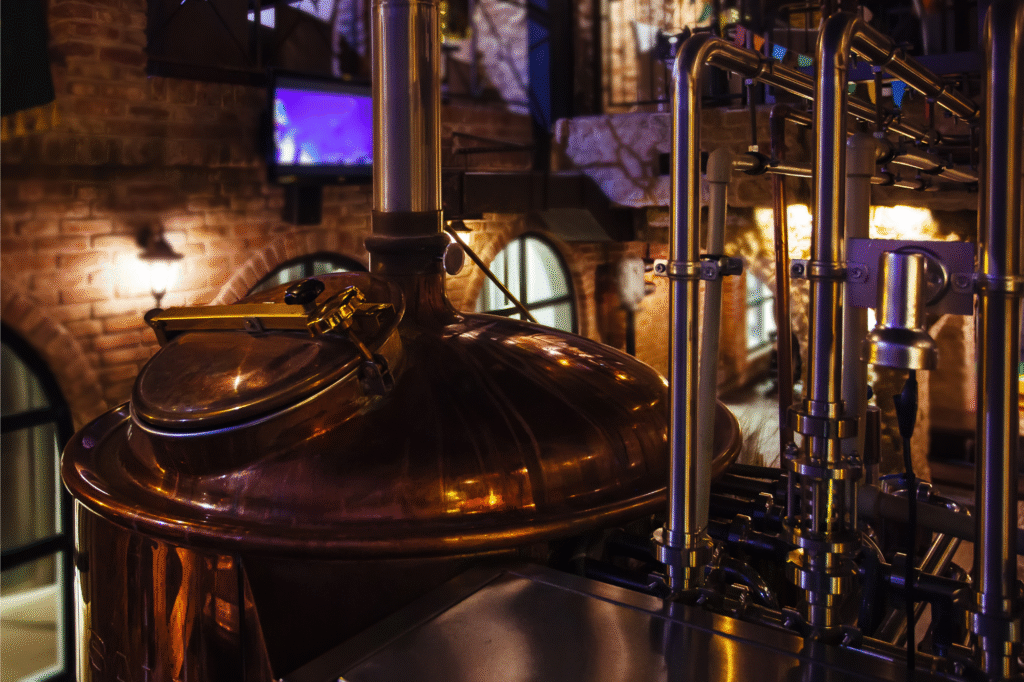

Core Components of a Beer Dispense System

Behind every perfect pour is a well-maintained, well-matched set of equipment. Each component of your beer dispense system plays a role in protecting flavour, consistency, and customer satisfaction. Let’s explore the four core parts and how they influence quality.

Keg Coupler

The keg coupler connects your keg to the rest of the dispense system, allowing gas in and beer out.

Why it matters:

- A secure, well-matched coupler ensures proper gas flow and stops contamination.

- If not cleaned regularly, it can introduce off-flavours or harbour bacteria.

- Using the wrong coupler for the keg type (e.g. A-type, Sankey, G-type) can lead to gas leaks, foaming, or no flow at all.

Maintenance tips:

- Clean couplers thoroughly every time you change a keg.

- Inspect seals and check for wear or corrosion.

- Ensure staff are trained to match couplers to keg types correctly.

CO₂ Gas Cylinder and Regulator

CO₂ is the force that moves beer from the keg to the glass, while also maintaining the beer’s natural carbonation. The regulator controls gas pressure delivered to the system.

Why it matters:

- Incorrect pressure leads to over-carbonation (foamy pours) or flat beer.

- Impure CO₂ introduces off-flavours like sulphur or benzene taints.

- Using low-grade or unfiltered gas can affect foam stability, aroma, and taste.

Maintenance tips:

- Use food-grade CO₂ that meets ISBT/EIGA standards.

- Regularly calibrate your regulator and check for pressure inconsistencies.

- Install a Sure Purity Carboguard filter to remove impurities from the gas line. This ensures clean, consistent carbonation and protects beer flavour from tap to glass.

Beer Lines

Beer lines carry the liquid from the keg to the tap. Their condition has a direct effect on flavour and pour quality.

Why it matters:

- Dirty lines can harbour yeast, mould, and bacteria, tainting the beer.

- Incorrect line length or diameter affects flow rate and can cause foaming.

- Build-up of residue leads to blockages or uneven pours.

Maintenance tips:

- Clean beer lines every 1–2 weeks using suitable cleaning agents.

- Check line length and diameter match your setup—longer runs need slower flow to reduce turbulence.

- Use insulated trunk lines where needed to maintain temperature.

Tap or Faucet

This is the final component where the beer meets the glass—and where presentation matters most.

Why it matters:

- A clean tap ensures foam is formed correctly and evenly.

- Flow-control faucets help maintain ideal pour speed and reduce turbulence.

- Dirty or sticky taps can ruin the first sip and damage customer perception.

Maintenance tips:

- Wipe down taps daily and deep clean weekly.

- Dismantle and sanitise the faucet regularly to prevent build-up.

- Check flow rates and ensure the faucet is suited to your beer style (e.g. slower for nitro pours, standard for lagers).

The Role of Gas Purity in Beer Quality

When most people think of CO₂ in beer, they picture the fizz. But for brewers, gas purity is about much more than bubbles. It’s about preserving taste, mouthfeel, aroma, and consistency from keg to glass.

CO₂ Is Part of the Product — Not Just a Propellant

Unlike soft drinks, where CO₂ is added purely for effervescence, in beer it plays a critical sensory role:

- Carbonation levels affect mouthfeel and head retention

- CO₂ helps carry aromas to the nose, enhancing flavour perception

- Consistent gas pressure ensures smooth delivery without disrupting the beer’s character

This means that whatever impurities are in your gas supply are being introduced directly into your product.

The Risks of Unfiltered CO₂

Using CO₂ that hasn’t been properly filtered can result in:

- Off-flavours: Harmful contaminants like benzene, hydrogen sulphide, or sulphur dioxide can introduce taints ranging from “rotten egg” to “chemical” notes

- Foam breakdown: Impurities interfere with foam structure, leading to poor head retention and inconsistent lacing

- Aroma loss: Polluted gas can mask or alter hop or malt aromas

- Health concerns: Trace toxins — even at low levels — may pose risks if the gas doesn’t meet food-grade standards

Inconsistent or poor-quality gas turns a carefully crafted beer into a disappointing pint. And often, the fault lies not with the beer or bar staff, but with what’s coming through the regulator.

What Food-Grade Really Means — and Why It Matters

In the UK and Europe, food-grade CO₂ should comply with recognised standards such as:

- ISBT (International Society of Beverage Technologists) guidelines

- EIGA (European Industrial Gases Association) standards

These define limits on moisture, hydrocarbons, volatile organic compounds, and other trace impurities. However, not all bottled CO₂ is created equal. Even food-grade gas can become contaminated through transport, storage, or ageing cylinders.

Enter Sure Purity’s Carboguard Filters

Our Carboguard and Carboguard mini are designed to safeguard beverage systems by filtering gas at the point-of-use — the last and most critical step before the CO₂ enters your beer.

Benefits of using Carboguard filters include:

- Removes benzene, sulphur, and other harmful contaminants

- Ensures consistent gas purity, regardless of supplier or cylinder age

- Protects the final taste, foam quality, and aroma of the beer

- Reduces the risk of customer complaints or rejected pours

Gas purity is often overlooked, but it’s the invisible backbone of a high-quality dispense system. By investing in food-grade filtration, you’re not just protecting equipment — you’re protecting your product, your customers, and your reputation.

Beer Dispense Equipment Setups: Matching Equipment to Environment

Not all beer dispense systems are created equal — and neither are the environments they’re used in. The ideal setup depends on the type of venue, the beer offering, and the service demands. From busy pubs to pop-up bars, choosing the right dispense system and maintaining gas purity are crucial to ensuring taste, foam, and service consistency.

Pubs and Bars

Most pubs and bars use long-draw systems, where beer is pushed from kegs in the cellar to taps at the bar, often over considerable distances.

Equipment needs:

- Wall-mounted CO₂ cylinders supplying a central gas bank

- Mixed gas blends (typically 60/40 or 70/30) to maintain correct carbonation across styles

- Pressure regulators tailored to each beer line

- Glycol cooling systems to keep beer cold in transit

Key risks:

- Pressure inconsistencies can cause flat or over-carbonated pours

- Line contamination from infrequent cleaning or poorly stored lines

- Foam collapse if gas purity is compromised by oil, moisture, or trace contaminants

Filtration relevance:

In high-volume settings, even minor gas impurities can be amplified across hundreds of pints per day. Point-of-use gas filtration, like Sure Purity’s Carboguard, ensures every pour meets taste and quality standards.

Impact on service:

- Faster, more consistent pours

- Less waste and fewer complaints

- Reliable foam and taste, even at peak times

Microbreweries and Taprooms

Smaller production venues and taprooms often favour direct-draw systems, where kegs sit directly beneath or behind the bar.

Equipment needs:

- Simple regulator and coupler connections

- Shorter beer lines

- CO₂ cylinders located nearby

- Coolers or chillers for maintaining temperature

Key risks:

- Limited gas blending can make it harder to fine-tune carbonation

- Gas contamination risks are higher if filters are not used

- Low-volume pours can exaggerate quality problems from even trace impurities

Filtration relevance:

When showcasing small-batch or craft beers, flavour preservation is essential. Sure Purity’s Carboguard filters remove impurities like sulphur and benzene that can taint delicate hop or yeast profiles.

Impact on service:

- Preserves freshness and clarity of artisan beers

- Builds trust in quality-conscious brewery brands

- Minimises loss from off-tasting or rejected pours

Mobile Bars and Events

Portable setups for weddings, festivals, or outdoor events have unique challenges due to space, mobility, and variable service conditions.

Equipment needs:

- Compact kegerators or cooler boxes

- Small CO₂ bottles (often without blending)

- Basic tap systems mounted on bars or counters

- Battery-powered regulators or pumps

Key risks:

- Gas contamination from reused or poorly stored bottles

- Unfiltered CO₂ leading to metallic or sulphuric taints

- No cooling system, meaning foam control becomes harder

Filtration relevance:

Portable setups benefit greatly from Carboguard Mini filters. These attach easily and maintain consistent CO₂ purity even in high-turnover or outdoor conditions.

Impact on service:

- Reliable beer quality in temporary setups

- Less foam waste during busy service windows

- Confidence in clean, drinkable beer regardless of location

Best Practice Tips for Maintaining Dispense Equipment

Even the best beer dispense equipment will fall short if it’s poorly maintained. Taste, foam quality and efficiency all rely on regular upkeep. For breweries, bars, and mobile setups alike, maintenance isn’t optional—it’s essential to delivering consistently great pints.

Clean Beer Lines Every 1–2 Weeks

Beer lines can quickly harbour yeast, mould, and biofilm. This leads to:

- Off-flavours and cloudy beer

- Inconsistent foam and lacing

- Potential hygiene risks

Best practice: Clean every 7 to 14 days using an approved line-cleaning solution. For high-volume venues, consider weekly cleans. Always rinse thoroughly with water before returning the line to service.

Fit a Carboguard Gas Filter at Point-of-Use

CO₂ purity is often overlooked. Yet unfiltered gas can contain:

- Sulphur compounds

- Benzene traces

- Moisture that affects carbonation

Solution: Use a Carboguard CO₂ filter or Parker DH alternative from Sure Purity. Our polishing filters remove impurities at the point-of-use, ensuring only clean, food-grade gas reaches your beer.

Carboguard is easy to install and works with standard systems, including mobile and direct draw setups. For small operations or portable bars, Carboguard Mini offers the same protection in a compact format.

Check CO₂ Pressure (PSI/Bar) Regularly

Incorrect pressure causes:

- Flat beer (too low)

- Excessive foam and gas wastage (too high)

- Carbonation inconsistency across different beer styles

Tip: Calibrate regulators for each line. Use a pressure gauge and adjust according to beer type and distance from keg to tap. Most ales perform best around 10–12 PSI, lagers slightly higher.

Store Cylinders Upright in a Ventilated Area

Cylinders should:

- Be stored upright and securely fastened

- Remain away from heat sources or direct sunlight

- Be kept in well-ventilated areas to prevent gas buildup in case of leaks

Why it matters: Proper storage protects safety, gas quality, and regulator performance. It also ensures you’re compliant with UK gas safety standards.

Train Staff on Dispense System Use

Staff should understand:

- How to connect and disconnect kegs properly

- The impact of gas pressure on pour quality

- The signs of dirty lines or contaminated gas

- Safe handling and storage of CO₂

Regular training reduces:

- Equipment damage

- Waste from poor pours

- Health and safety risks

Keep a Maintenance Log

It helps track:

- Cleaning schedules

- Gas cylinder replacements

- Filter changes (like Carboguard every 6–12 months)

- Regulator inspections

Bonus benefit: A logbook supports quality audits and shows your team is serious about delivering top-tier beer.

Maintaining beer dispense equipment isn’t complicated, but it does require consistency. Clean lines, correct pressure, filtered gas, and trained staff form the backbone of a reliable, high-quality system.

Quality Beer Starts Behind the Tap

A great pint doesn’t start in the glass—it starts with the equipment behind the bar.

Every element of your beer dispense system, from the coupler to the tap, plays a role in what ends up in the customer’s hand. Get it right, and you deliver perfect flavour, foam, and consistency. Get it wrong, and you risk flat beer, waste, and disappointed customers.

One of the most overlooked elements? The gas.

CO₂ isn’t just a propellant. It directly affects taste, mouthfeel, and foam stability. If your gas is unfiltered or poorly regulated, it can undo all the care that went into brewing the beer in the first place.

Our Carboguard filtration systems are designed to protect beverage quality at the source. Right where the gas enters your system. Whether you run a bar, brewery, or mobile taproom, clean CO₂ gives you better pours, less waste, and fewer problems.

Take a moment to assess your current setup:

- Are your lines cleaned regularly?

- Is your gas filtered at the point of use?

- Are your PSI settings tuned to the beer styles you serve?

- Could your team benefit from updated training or equipment?

If any of those answers raise doubt, it might be time to re-evaluate. Investing in better gas filtration and dispense equipment maintenance isn’t just about performance—it’s about protecting your brand and enhancing customer experience.

Explore the Carboguard range or contact our technical team to discuss the right solution for your venue. Because clean beer starts with clean systems—and quality always starts behind the tap.