You’ve brewed the perfect batch—balanced, flavourful, and ready to serve. But there’s a catch: it needs to be carbonated fast. Whether you’re preparing for a product launch, restocking taps, or speeding up production, waiting weeks for natural carbonation simply isn’t an option.

That’s where force carbonation comes in. This method allows brewers to add precise levels of CO₂ quickly and efficiently, reducing wait times and improving consistency. But it’s not as simple as just turning up the gas. Without the right pressure, temperature control, and gas purity, you risk over-carbonated foam bombs—or worse, flat beer with off flavours.

In this guide, we’ll cover everything you need to know to force carbonate your beer the right way. You’ll learn:

- What force carbonation is and why it matters

- The different methods used by commercial brewers and homebrewers

- How pressure and temperature affect results

- Common mistakes to avoid

- Why CO₂ purity matters

Let’s dive in and help you deliver perfect pints, faster.

What Is Force Carbonation?

Force carbonation is the process of adding carbon dioxide (CO₂) directly into beer under pressure to create fizz. Unlike natural carbonation, where CO₂ is produced slowly during secondary fermentation, this method allows you to carbonate beer quickly and with precision.

How it works:

Once the beer is transferred to a sealed keg or vessel, CO₂ gas is introduced at a controlled pressure. Over time, the gas dissolves into the liquid. The colder the beer and the higher the pressure, the faster and more effectively this happens.

Force Carbonation vs Natural Carbonation

- Natural carbonation occurs when live yeast ferments residual sugars in sealed containers, creating CO₂.

- Force carbonation bypasses this step by injecting CO₂ directly, offering immediate control over carbonation levels.

Why Brewers Prefer Force Carbonation

For commercial breweries, time is money. Force carbonation enables:

- Faster turnaround times – beer can be ready for packaging or dispensing within 24–72 hours.

- Consistent CO₂ levels – essential for meeting product specs and customer expectations.

- Fewer variables – no need to rely on residual sugar, yeast health, or exact conditioning times.

Whether you’re scaling production or ensuring your kegged beer meets a specific carbonation target, force carbonation delivers speed, reliability, and repeatable quality.

Why Gas Purity and Pressure Matter

When force carbonating beer, it’s not just about pressure—it’s about what’s in the gas you’re using. Poor-quality CO₂ can taint your product, ruin flavour, and put consumer safety at risk. That’s why gas purity and pressure stability are non-negotiables for commercial brewers.

What Is Food-Grade CO₂?

Food-grade CO₂ is carbon dioxide that meets strict safety and purity requirements set by bodies like ISBT (International Society of Beverage Technologists) and EIGA (European Industrial Gases Association). These standards ensure the gas is free from harmful contaminants such as:

- Sulphur compounds (which create rotten egg aromas)

- Oil vapour or hydrocarbons (which alter mouthfeel and foam)

- Excess moisture, which can affect carbonation efficiency and promote microbial growth

Using industrial-grade CO₂, or CO₂ from unfiltered sources, carries a real risk of introducing these contaminants into your beer.

Contaminated Gas = Compromised Beer

Even a trace amount of tainted gas can result in:

- Off-flavours like burnt rubber, metallic, or sulphurous notes

- Inconsistent carbonation levels due to pressure fluctuations

- Foaming issues at dispense

- Increased risk of infection due to moisture or impurities in the gas lines

The Role of Sure Purity Filtration

Sure Purity’s Carboguard and Carboguard Mini are specialist CO₂ filtration systems designed for breweries and beverage producers. These inline filters:

- Remove oil vapour, particulates, and water from gas lines

- Comply with ISBT/EIGA food and beverage gas standards

- Ensure clean, dry, consistent CO₂ is delivered to your beer

- Extend equipment lifespan and reduce system maintenance

For brewers who use mixed gas or rely on external gas suppliers, Sure Purity’s Carbo-Alt filter offers similar protection for alternative gas blends, keeping nitrogen and mixed-gas systems safe and clean too.

Stable Pressure = Stable Carbonation

Clean gas is only part of the equation. Maintaining a stable pressure level throughout the carbonation process is essential. Pressure that’s too high risks over-carbonation and excess foam. Too low, and the beer turns out flat or under-carbonated.

Filtered CO₂ helps avoid these fluctuations, delivering precise carbonation control and flavour consistency—batch after batch.

3 Force Carbonation Methods Explained

There are several ways to force carbonate beer, each with different speeds, precision levels, and risks. Below are the three most common methods used by brewers, ranging from slow and steady to fast and hands-on.

Set and Forget Method

This is the most reliable and consistent method—favoured by many commercial brewers for its precision.

- How it works:

Connect the keg to CO₂ and set the regulator to 10–12 PSI. Store the keg at a constant 3–4°C and leave it for 5–7 days. During this time, CO₂ is gradually absorbed into the beer until it reaches equilibrium. - Benefits:

- Minimal risk of over-carbonation

- Gentle absorption ensures stable mouthfeel and flavour

- No need for constant supervision

- Risks:

- Slower turnaround—requires planning in production schedules

- Unsuitable for last-minute batch corrections

This is ideal when product consistency and quality control matter more than speed.

Burst Carbonation (Quick Carb)

Used when beer needs to be carbonated fast, often by smaller breweries or to meet sudden demand.

- How it works:

Increase the CO₂ pressure to 30 PSI and keep the beer cold (below 4°C) for 12–24 hours. Once carbonated, reduce the pressure to serving level (10–12 PSI) and allow it to settle. - Benefits:

- Much faster than the set-and-forget method

- Good for urgent batches or test brews

- Doesn’t require rocking or constant manual work

- Risks:

- High pressure can over-carbonate beer

- Needs careful monitoring to avoid foaming or inconsistent mouthfeel

- Slight risk of flavour distortion if the pressure fluctuates

Best used with filtered, stable CO₂ to minimise these risks, where Sure Purity filters offer added safety.

Rock & Roll Method (for Homebrewers)

This method is popular among homebrewers looking for speed without specialist equipment, but it’s rarely used in commercial settings.

- How it works:

After chilling the keg, set the pressure to around 30 PSI, then gently rock or shake the keg for several minutes to help the gas dissolve more rapidly. Let it rest for an hour or two, then test carbonation levels. - Benefits:

- Very fast—results in just a few hours

- No need to wait several days

- Risks:

- High risk of over-carbonation or inconsistent CO₂ absorption

- Can cause excessive foaming or flat spots

- Unsuitable for commercial breweries—too variable and labour-intensive

This method is best kept for home setups, not production lines. Commercial brewers need precision, consistency, and compliance, which means filtered gas, monitored pressure, and well-tested methods.

PSI, Temperature & CO₂ – Getting the Balance Right

Force carbonation isn’t just about blasting CO₂ into a keg. It’s a careful balance between pressure, temperature, and solubility. Get one wrong, and your beer could end up flat, foamy, or worse—off-flavour.

The Science Behind It

CO₂ dissolves into beer more easily at lower temperatures and higher pressures. This means:

- Colder beer = more CO₂ absorption at lower PSI

- Warmer beer = needs higher PSI for same carbonation

If you apply too much pressure at too high a temperature, you risk over-carbonation, foaming, and wasted product. If your beer is too cold with not enough pressure, it won’t carbonate properly.

Using Carbonation Charts

Standard carbonation charts are used by brewers to work out the right PSI setting for a given temperature and target CO₂ volume. These charts are essential to get the outcome you want.

Example:

If you’re carbonating an IPA to 2.5 volumes of CO₂ at 4°C, you’ll need to set your regulator to around 12 PSI.

These charts give you a reliable reference point, but only if your gas supply is consistent and your system is leak-free.

Why Filtered Gas Matters

Even when you set the correct PSI and temperature, contaminated CO₂ can lead to unstable carbonation, pressure spikes, and line blockages. Moisture and particulates in unfiltered gas can freeze in regulators or restrictors, especially in colder environments.

That’s why Sure Purity’s Carboguard and Carboguard Mini filters are essential tools. They remove moisture, oil, and contaminants from gas lines. This ensures a clean, stable CO₂ supply that delivers accurate pressure and protects equipment.

Blending for Different Beer Styles

Some beer styles require mixed gas (e.g., 70/30 CO₂/Nitrogen) to achieve lower carbonation levels with a smoother pour—think stouts or nitro ales. For this, Sure Purity’s Carbo-ALT system offers a safe, compliant way to blend gases accurately, helping brewers maintain consistency across different beer styles.

Getting the balance right isn’t just good science—it’s good business. Stable carbonation means better taste, better shelf life, and better customer satisfaction.

Equipment Needed for Force Carbonation

To successfully force carbonate beer—whether you’re a commercial brewer or home enthusiast—you’ll need a few essential components to ensure safety, accuracy, and quality. Here’s a checklist:

- CO₂ Tank (Food-Grade):

Use a food-grade gas cylinder certified to ISBT/EIGA standards to ensure purity and avoid off-flavours. - Regulator with Dual Gauge:

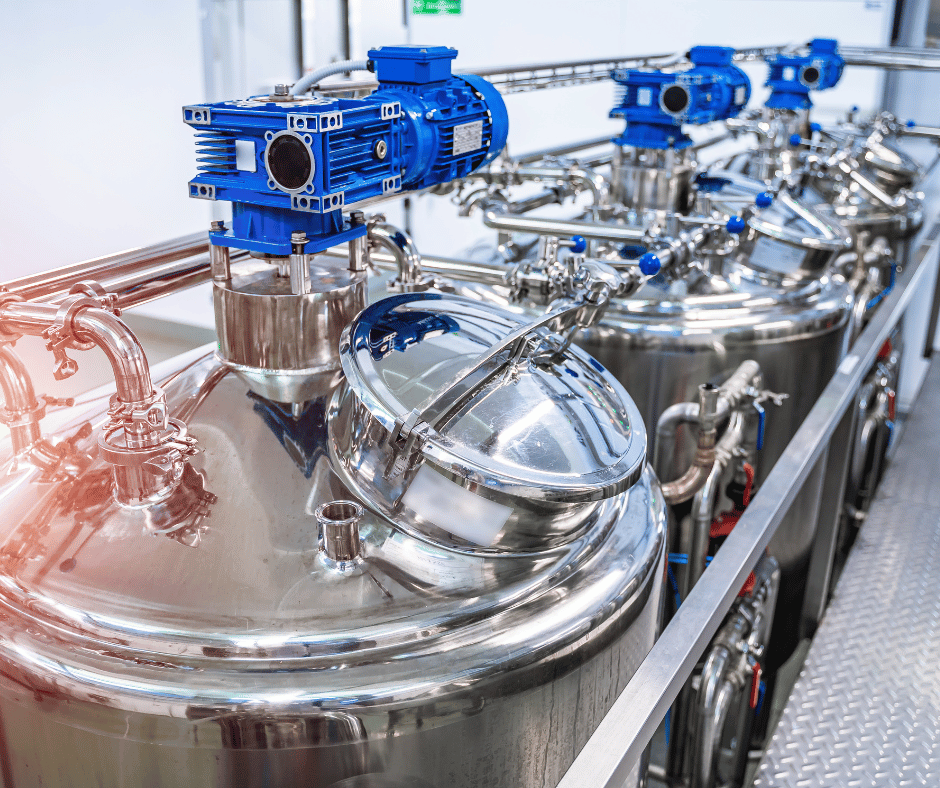

One gauge shows the cylinder pressure, the other shows output pressure to the keg. Precision is crucial when working at varying PSI levels. - Beer Keg (Corny or Commercial):

Cornelius kegs for homebrewers; stainless steel commercial kegs for breweries. - Beer and Gas Line Tubing:

Rated for pressure and food-safe. Keep lines clean and free of moisture to avoid contamination. - Temperature Control (Cellar, Fridge, or Glycol System):

Consistent cold temperatures (around 3–4°C) are essential for predictable carbonation. - Sure Purity Carboguard or Carboguard Mini Filters:

These inline filters remove moisture, oil, and particulates from gas lines, helping maintain stable pressure and prevent freeze-ups or taints. - Optional – Carbonation Stone or Diffuser:

Used especially in packaging lines, a carbonation stone increases the surface area for CO₂ absorption—speeding up the process.

Commercial Carbonation Tips (for Breweries)

Precision is everything in commercial brewing. Especially when it comes to carbonation. Here’s how to get consistent results while protecting the integrity of your beer and your system:

- Use a Gradual Approach for Delicate Styles:

Beers like lagers, hazy IPAs, and sours benefit from slow carbonation at 10–12 PSI over several days. This avoids disrupting flavour compounds and helps preserve mouthfeel. - Filter Your CO₂ to Protect Flavour:

Unfiltered gas can introduce impurities like oil, moisture, or odour—spoiling batch consistency. Sure Purity’s Carboguard and Carboguard Mini filter out these contaminants inline, maintaining clean pressure delivery and flavour purity. - Use Carboguard Mini in Kegging or Brite Tanks:

Ideal for compact setups, the Mini ensures food-grade gas purity where CO₂ enters the product—vital for craft breweries or mobile kegging units. - Scale Up with Carbo-ALT for Blended Gas Applications:

For breweries using mixed gases (CO₂ and nitrogen), Sure Purity’s Carbo-ALT offers a regulated, EIGA-compliant solution. It’s perfect for nitrogenated styles and draft systems that require controlled gas blends. - Clean-in-Place (CIP) Protocols Matter:

Carbonation stones and regulators should be cleaned and sanitised regularly. Build-up in porous stones or valve systems can affect carbonation flow or introduce contaminants. Always use CIP-compatible setups and follow brewery SOPs.

Common Mistakes to Avoid

Avoid these frequent carbonation pitfalls to improve quality, efficiency, and consistency:

- Using non-food grade CO₂

Can introduce sulphur, oil, or solvent-like flavours into the beer. - Over-pressurising too quickly

Causes excess foam, over-carbonation, and waste during packaging. - Not chilling beer before carbonation

Warm beer absorbs CO₂ poorly, leading to under-carbonation or slow conditioning. - Forgetting to purge oxygen from the keg

Leads to oxidation, dull flavours, and shortened shelf life. - Dirty or contaminated gas lines

Allow microbial or chemical taints into the system, risking batch-wide flavour issues. - Poor CO₂ regulator calibration

Inconsistent pressure causes irregular carbonation or pressure spikes during service.

Carbonate Beer the Smart, Clean Way

Force carbonating beer isn’t just about hitting the right PSI. It’s about protecting quality from start to finish. The best results come from:

- Using chilled beer for better CO₂ absorption

- Applying the right pressure for the chosen carbonation method

- Ensuring clean, food-grade CO₂ from a reliable source

For commercial brewers, carbonation is more than a one-off task—it’s part of a broader hygiene and quality control system. Poor gas quality, pressure spikes, or contaminated equipment can lead to costly batch issues and unhappy customers.

That’s why gas filtration matters.

Sure Purity’s Carboguard, Carboguard Mini, and Carbo-ALT products are designed to protect the flavour, consistency, and safety of every pint you pour—supporting brewers of all sizes with clean, regulated gas performance.

Contact us today to futureproof your carbonation setup and maintain quality in every batch.