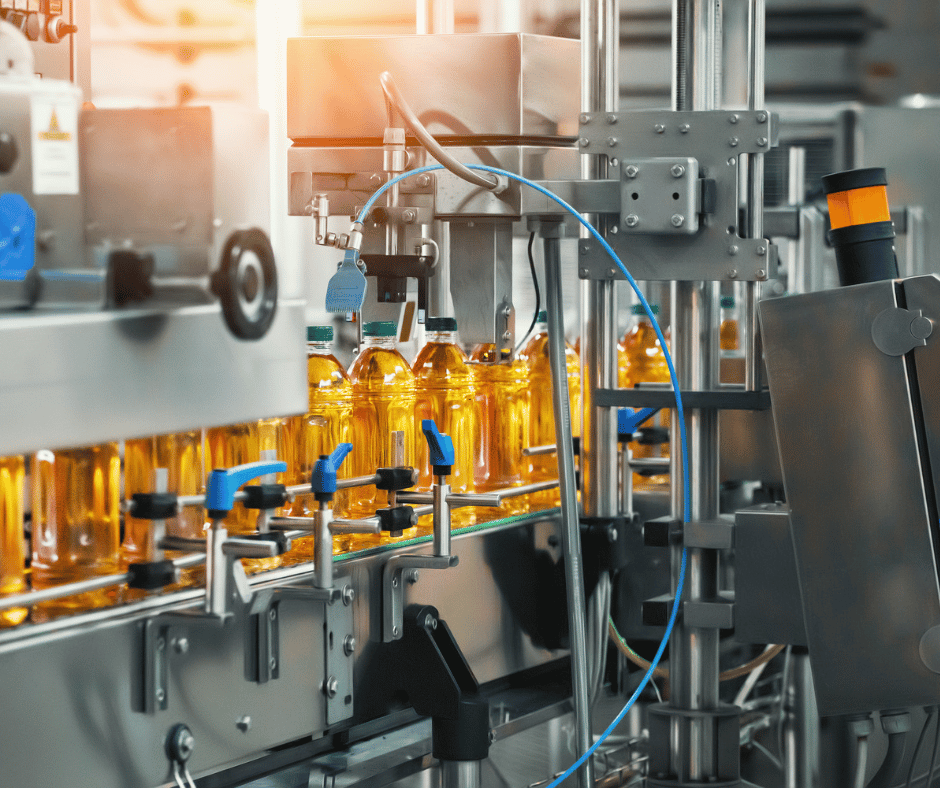

In beverage production, gas quality has a direct impact on taste, safety, and reputation. Every pint, bottle, or glass depends on one often-overlooked ingredient – carbon dioxide.

CO₂ is essential for carbonation and dispense pressure, but its quality can vary more than many producers realise. Even gas labelled as “beverage-grade” can contain trace impurities that affect flavour, aroma, and shelf life. These invisible contaminants move through supply chains unnoticed, entering carbonation or dispense systems undetected.

Testing gas quality ensures that the CO₂ used in your process meets the purity levels expected by both consumers and global standards such as ISBT and EIGA. Regular testing helps breweries, beverage manufacturers, and hospitality operators maintain consistent quality, reduce product loss, and protect brand reputation.

In this guide, you’ll learn how to test gas quality in beverage systems, when testing should be carried out, and how multi-stage filtration – such as Sure Purity’s Carboguard technology – prevents contamination between tests.

Why Gas Quality Testing Is Essential

CO₂ plays a far greater role in beverage production than most realise. It carbonates the drink, carries aroma compounds, and maintains pressure during dispense. When the gas is impure, it can quietly compromise every stage of production.

Even minor contamination can lead to big problems – strange odours, tainted flavours, and poor carbonation are common signs of CO₂ quality issues. In serious cases, contamination causes product spoilage, stock loss, and damaged customer trust.

Many producers assume that if their gas is labelled “beverage-grade”, it’s completely pure. However, certification alone doesn’t guarantee quality at the point of use. Between the gas supplier and your carbonation system, impurities can be introduced through transport, storage, or ageing pipelines.

That’s why testing matters. Regular gas analysis verifies that the CO₂ entering your system still meets purity standards. It also allows you to detect trace compounds such as hydrogen sulphide, hydrocarbons, and carbonyl sulphide – all of which can create off-flavours or odours that ruin an otherwise perfect drink.

Industry organisations such as the International Society of Beverage Technologists (ISBT) and the European Industrial Gases Association (EIGA) both recommend ongoing monitoring of gas purity as part of beverage quality assurance. Their standards form the basis of global best practice, helping ensure that gas purity remains consistent throughout production.

If you’ve ever poured a pint that smelled “off” despite clean lines, your CO₂ supply could be the culprit.

What to Look For When Testing CO₂ Quality

When testing gas quality in beverage systems, knowing what to look for is essential. Even trace levels of certain contaminants can change how a drink tastes, smells, or looks. Identifying these impurities early helps protect consistency and maintain high product standards.

Key Contaminants to Monitor

Hydrogen Sulphide (H₂S)

Hydrogen sulphide is one of the most common and recognisable contaminants found in CO₂. It produces a strong, sulphurous odour often compared to rotten eggs. Even in very low concentrations, it can spoil a beer’s aroma and mask delicate flavours. In extreme cases, it makes a drink undrinkable.

Testing for H₂S is vital because it’s invisible to the eye yet highly detectable by smell. Continuous monitoring ensures any trace presence is caught before gas enters the production line.

Carbonyl Sulphide (COS)

Carbonyl sulphide is another sulphur-based compound that creates a chemical or “burnt” taste. It forms during certain industrial gas processes and can slip through the supply chain if not properly filtered. COS lingers in the gas stream and interacts with the beverage, leading to a persistent off-taste that standard cleaning can’t remove.

Advanced CO₂ polishing systems, such as those using Sure Purity’s multi-stage filtration, are specifically designed to eliminate COS before it affects product quality.

Hydrocarbons

Hydrocarbons, including aromatic and aliphatic compounds, can enter CO₂ supplies from production or transportation stages. These compounds often cause oily, plastic-like flavours or unwanted aromas that customers quickly notice.

Although hydrocarbons are not usually present in high concentrations, they can still damage the sensory experience. Testing for hydrocarbons ensures that the CO₂ remains neutral and flavourless, as it should be.

Moisture and Particulates

Moisture and particulates don’t necessarily change flavour, but they can interfere with equipment and dispense performance. Excess water can lead to corrosion or bacterial growth in pipelines, while solid particles can block valves or regulators.

Regular gas quality analysis should include checks for moisture content and particle levels to maintain consistent pressure and reliable operation across all beverage systems.

Oxygen

Oxygen is another key contaminant that must be controlled. It accelerates oxidation, reducing shelf life and causing subtle but noticeable flavour deterioration. Over time, oxidised drinks develop flat, cardboard-like notes and lose their fresh aroma.

Proper CO₂ testing and purification prevent oxygen intrusion, ensuring the product tastes as intended for longer.

Approved Methods for Testing CO₂ Gas Quality

Testing CO₂ quality requires accurate, reliable methods that reveal even the smallest trace of contamination. Whether you operate a brewery, bottling plant, or dispense system, choosing the right testing approach helps you stay compliant, consistent, and confident in every batch.

Laboratory Testing

Laboratory analysis remains the gold standard for CO₂ purity testing. It provides the highest accuracy when identifying trace contaminants such as hydrogen sulphide, carbonyl sulphide, and hydrocarbons.

The most common method is gas chromatography (GC). This analytical technique separates gases within a sample to identify and measure specific impurities, even at parts-per-billion levels. It’s ideal for confirming the presence of trace compounds that could affect flavour, odour, or carbonation stability.

To carry out laboratory testing, samples are collected directly from the CO₂ line or storage cylinder. Proper collection is critical. Containers must be sterile, sealed, and labelled to prevent cross-contamination. Most breweries and beverage manufacturers work with accredited laboratories or independent gas testing specialists who follow recognised procedures under ISBT or EIGA guidelines.

While lab testing isn’t required daily, it provides the most detailed snapshot of CO₂ quality. Many producers schedule this quarterly or after supplier changes to ensure ongoing compliance and product consistency.

Portable CO₂ Testing Devices

For day-to-day checks, portable CO₂ analysers or inline testing devices are an excellent option. These handheld units measure common contaminants like moisture, hydrocarbons, and oxygen on-site, giving technicians instant feedback on gas quality.

Portable devices are especially useful for breweries or restaurants that want fast answers without waiting for lab results. They’re cost-effective, simple to use, and allow for frequent routine monitoring. Inline analysers can even connect directly to CO₂ pipelines, providing continuous data to help detect sudden purity drops or leaks before they impact production.

Using portable analysers alongside laboratory testing gives the best of both worlds — immediate results and long-term assurance.

Supplier Certificates and Verification

Every gas supplier should provide a Certificate of Analysis (COA) with each batch of CO₂. This document lists measured levels of key contaminants and confirms compliance with beverage-grade CO₂ standards under ISBT and EIGA regulations.

While these certificates are valuable, they shouldn’t replace your own quality checks. Conditions can change between the supplier’s plant and your carbonation system. Testing the gas on-site verifies that purity is maintained through transport, storage, and delivery.

Verifying supplier results through third-party testing or in-house analysis ensures accountability. It also protects your brand by confirming that the gas you receive (not just the gas they produce) meets the same strict standards your customers expect.

When and How Often to Test CO₂ Quality

Testing CO₂ quality isn’t a one-time task. It’s an ongoing process that keeps your beverage systems performing consistently. Regular testing confirms that the gas entering your system remains pure, even as equipment, suppliers, and operating conditions change.

Routine Testing Intervals

Most breweries and beverage producers benefit from scheduled testing throughout the year. For breweries, quarterly testing is recommended to maintain continuous control and early detection of impurities. For larger, high-volume producers, biannual testing may be sufficient if additional safeguards, such as CO₂ polishing filtration, are in place.

Testing frequency should reflect production scale, risk tolerance, and how critical CO₂ quality is to your product profile. In industries where sensory precision matters, such as craft brewing or soft drink manufacturing, more frequent testing offers extra peace of mind.

Test After Key Changes or Events

While routine checks are essential, certain events should always trigger additional testing:

- Supplier changes: New suppliers may have different production processes, storage methods, or quality control standards. Testing verifies consistency before integration into your system.

- Equipment maintenance: Replacing or repairing regulators, pipelines, or storage vessels can introduce contaminants. Post-maintenance testing ensures the gas path is clean and secure.

- Customer complaints or product issues: If you notice unusual flavours, odours, or carbonation problems, testing helps confirm whether CO₂ contamination is the cause.

- New gas storage or pipeline installations: New components may release particulates or residues that affect gas purity. Testing validates that everything is performing correctly from the start.

Creating a Testing Protocol

Establishing a formal CO₂ testing protocol turns good practice into standard procedure. A written protocol should outline:

- Testing frequency and responsible personnel

- Sampling points within the CO₂ line

- Testing methods and equipment to be used

- Record-keeping and data storage processes

Keeping detailed quality records is equally important. Documenting test results builds traceability, supports compliance audits, and demonstrates a commitment to continuous quality assurance. It also helps identify trends over time, such as gradual increases in moisture or hydrocarbon levels, before they affect production.

Preventing Contamination Between Tests

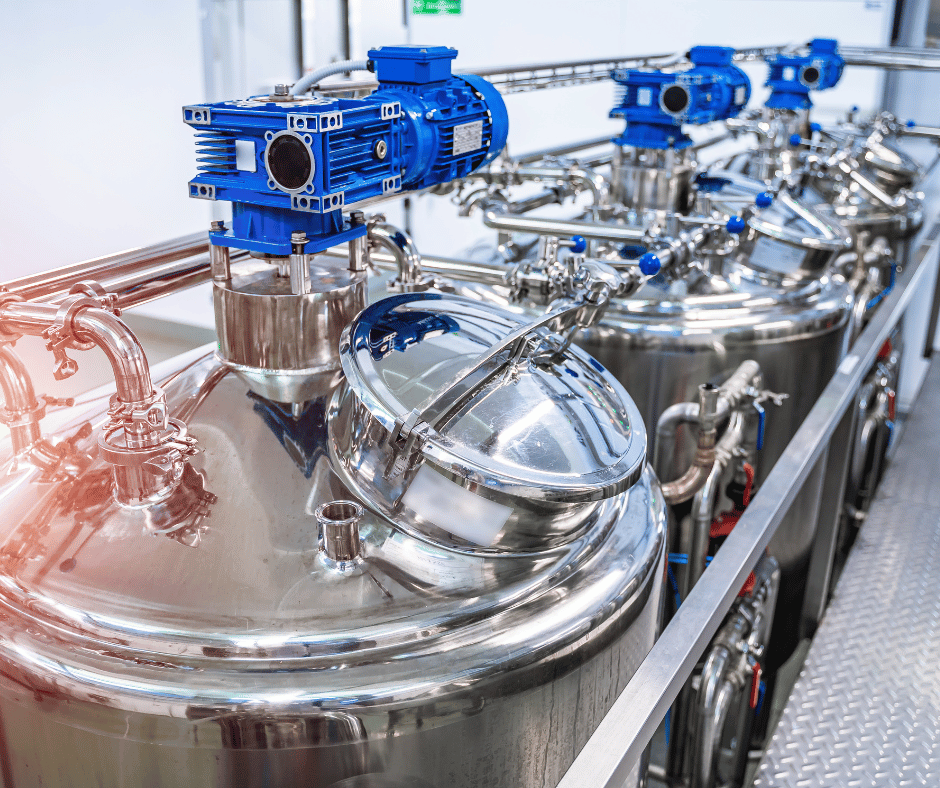

Testing confirms gas purity, but filtration keeps it that way. While analysis helps identify contamination, it doesn’t stop it from reoccurring. To truly protect beverage quality, producers must prevent impurities from entering the system in the first place.

Why Filtration Completes the Process

Gas purity can fluctuate between testing intervals due to changes in storage, handling, or supplier conditions. Even small variations in moisture, hydrocarbons, or sulphur compounds can compromise flavour and aroma. That’s why proactive prevention is just as important as testing itself.

Installing a multi-stage CO₂ polishing system provides continuous protection. It acts as a final safeguard, removing trace contaminants in real time before the gas reaches your carbonation or dispense line.

How CO₂ Polishing Systems Work

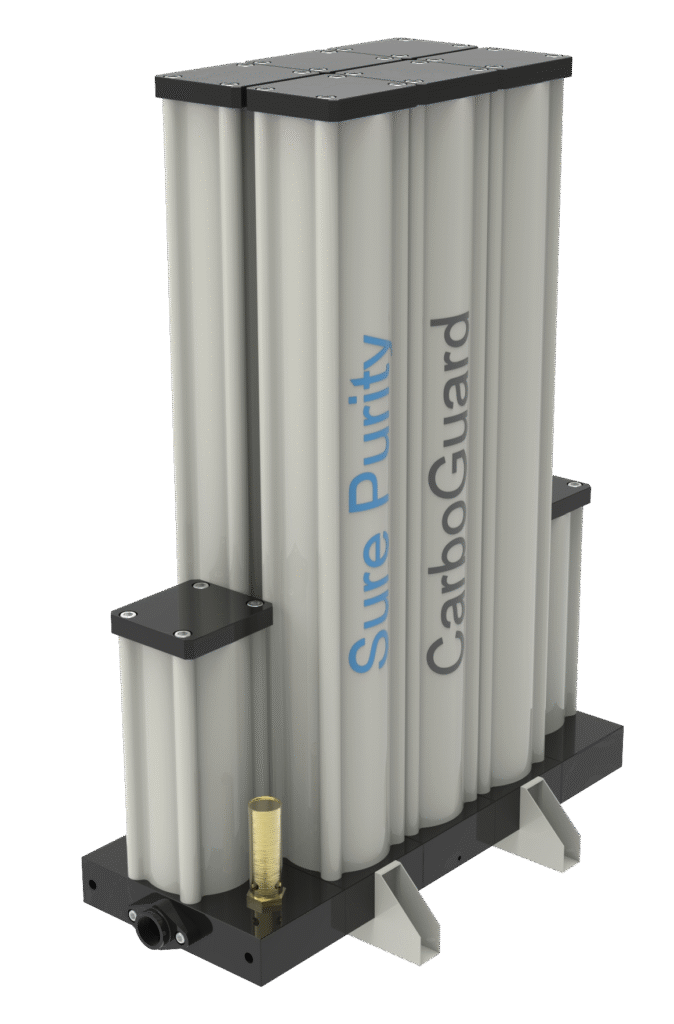

Multi-stage systems, such as Sure Purity’s Carboguard range, filter CO₂ through a series of media layers designed to target different impurities. Each stage traps or neutralises specific contaminants – from hydrogen sulphide and carbonyl sulphide to hydrocarbons and particulates.

This process ensures only pure, odourless, and taste-neutral CO₂ enters the beverage system. It also stabilises carbonation performance, improving consistency across every pour or production run.

Unlike traditional filters, our Carboguard technology maintains gas flow while delivering up to ten times more protection than standard ISBT guidelines. Its snowstorm media filling design increases contact efficiency by 12%, maximising impurity removal and maintaining consistent flow rates.

Key Benefits of CO₂ Filtration

- Consistent gas purity: Continuous polishing keeps CO₂ within ideal quality limits at all times.

- Protection against trace contaminants: Removes the invisible compounds that cause flavour, odour, and dispense issues.

- Fewer product quality problems: Reduces the risk of carbonation faults, customer complaints, and costly product recalls.

- Extended system lifespan: Prevents corrosion, blockages, and wear caused by impurities in the gas stream.

Best Practices for Maintaining CO₂ Quality

Maintaining CO₂ purity requires consistent habits, not just occasional testing. Small changes in handling, maintenance, or documentation can have a big impact on beverage quality. Following these proven practices helps ensure every drink meets the same high standard.

1. Use ISBT and EIGA-Approved Gas Suppliers

Start with a reliable source. Always work with ISBT and EIGA-approved gas suppliers who meet strict beverage-grade CO₂ standards. These organisations define the global benchmarks for gas purity and safety.

When purchasing gas, request up-to-date compliance documentation and a Certificate of Analysis (COA) for each batch. The certificate should include test results for hydrogen sulphide, hydrocarbons, moisture, and oxygen levels.

Even if your supplier provides certified gas, it’s worth verifying through your own testing schedule. Gas can become contaminated during transport or storage, and on-site checks ensure that the purity you pay for is the purity you receive.

2. Install CO₂ Filtration

Testing alone doesn’t stop contamination, filtration does. Installing CO₂ polishing filters provides continuous protection and removes impurities before they reach your production line.

For beverage dispense systems such as bars, restaurants, and fast-food chains, the Carboguard Mini offers compact, high-performance filtration. It targets trace contaminants that cause off-flavours, odours, and carbonation problems at the point of dispense.

For breweries and larger beverage producers, the Carboguard Craft delivers the same multi-stage purification on a scale suited to high-volume CO₂ use. Both models are designed for simple installation, minimal maintenance, and long-lasting efficiency.

Adding filtration ensures CO₂ remains clean, odour-free, and compliant between testing cycles.

3. Maintain Clean Gas Lines

Even the purest CO₂ can pick up impurities if it travels through poorly maintained lines. Over time, moisture, oil, or debris can build up, leading to inconsistent dispense pressure or contamination.

Schedule regular line inspections and cleaning to prevent residue buildup and cross-contamination. Focus on connectors, valves, and storage cylinders, where particulates often accumulate unnoticed. Clean gas pathways help maintain carbonation control, protect equipment, and preserve the sensory quality of the final beverage.

4. Keep Records and Track Quality

Accurate documentation is one of the simplest yet most effective quality tools. Keep a detailed record of testing results, COA certificates, maintenance dates, and filter replacements.

This information supports internal audits, compliance inspections, and traceability reports. It also helps identify trends, such as increasing impurity levels, before they become serious issues.

Interpreting CO₂ Test Results

Once testing is complete, understanding what the results mean is vital. Each test provides valuable insight into your CO₂ supply and helps confirm whether it meets the required standards for beverage applications.

Understanding Acceptable Thresholds

Industry standards, such as those set by the International Society of Beverage Technologists (ISBT) and the European Industrial Gases Association (EIGA), define acceptable limits for common contaminants.

While exact figures vary by application, beverage-grade CO₂ typically must contain:

- Less than 0.1 parts per million (ppm) hydrogen sulphide

- Less than 1 ppm total hydrocarbons

- Less than 0.5 ppm carbonyl sulphide

- Oxygen levels below 30 ppm

- Minimal detectable moisture content

Results above these levels may not pose immediate safety risks, but they can cause noticeable sensory changes. Even tiny variations can alter carbonation performance or create unwanted flavours and odours.

Interpreting results correctly allows you to take early corrective action and avoid larger quality issues later.

When CO₂ Fails to Meet Standards

If test results exceed acceptable limits, take immediate steps to isolate the issue and restore purity:

- Contact your gas supplier. Share the results and request a replacement batch or clarification on their quality assurance procedures.

- Inspect storage and delivery lines. Contamination can occur within your own system through leaks, moisture buildup, or corroded fittings.

- Replace or install filtration units. Multi-stage CO₂ polishing systems such as Carboguard remove the trace contaminants that often slip through traditional supply chains.

Addressing the source of contamination quickly prevents further disruption and protects both your brand and product integrity.

Final Thoughts

Testing CO₂ quality isn’t just a compliance exercise – it’s an investment in your reputation, product quality, and customer trust. By combining regular testing with effective filtration, you create a continuous cycle of protection that keeps your beverage systems performing at their best.

Sure Purity’s Carboguard range is designed to safeguard beverage producers against the hidden risks of CO₂ contamination. With multi-stage filtration technology and measurable performance benefits, it delivers cleaner gas, better flavour consistency, and longer-lasting system reliability.

Ensure your CO₂ meets the highest purity standards. Explore how our Carboguard range safeguards beverage quality from gas source to glass.