How much CO₂ is in the atmosphere? Today, atmospheric carbon dioxide levels sit at around 420 parts per million — just 0.04% of our air. But this small percentage plays a big role in climate change, global warming, and industry accountability.

For the drinks and hospitality industry, carbon dioxide is more than just a greenhouse gas — it’s a critical part of production. It carbonates soft drinks, pressurises kegs, and protects packaging. But sourcing, purifying, transporting, and venting CO₂ all carry an environmental cost. Every cylinder filled, every filter replaced, and every gas vented contributes to a business’s carbon footprint.

That’s where Sure Purity comes in.

Our long-life gas filtration systems reduce solid waste by up to 50% compared to traditional purification methods. That’s fewer filters changed, less waste sent to landfill, and lower emissions from manufacturing and disposal. For drinks producers, bottlers, bars, and breweries, it’s a smart way to lower environmental impact without compromising on gas quality.

In this guide, we’ll explore:

- How much CO₂ is in the atmosphere and why it matters

- What percentage of CO₂ is natural vs man-made

- How the drinks industry contributes to CO₂ levels through gas systems

- How Sure Purity’s filters support waste reduction and sustainability goals

- Actionable steps to reduce your CO₂ footprint in beverage production or dispensing

Whether you run a bar, manage a brewery, or oversee gas supply logistics, this article offers insight into the bigger carbon picture — and how you can play a part in reducing it.

How Much CO₂ Is in the Atmosphere?

Today, the amount of CO₂ in the Earth’s atmosphere is just over 420 parts per million (ppm). That might sound small — only around 0.04% of the air we breathe — but its impact on the planet is significant.

Why This Tiny Percentage Matters

CO₂ is a greenhouse gas, meaning it traps heat in the atmosphere. While it makes up a small portion of air, it plays a large role in climate regulation. Since the industrial revolution, human activity has driven CO₂ levels sharply upward — from 280 ppm in the 18th century to over 420 ppm today.

This rise in atmospheric CO₂ contributes directly to:

- Global warming and extreme weather

- Melting ice caps and rising sea levels

- Environmental policy changes and stricter regulations for industries

For businesses operating in energy-intensive sectors — including drinks production and beverage gas supply — this data isn’t just scientific. It’s part of the environmental performance metrics being tracked by investors, regulators, and customers alike.

What Percentage of CO₂ in the Atmosphere Is Natural?

Roughly 95–97% of atmospheric CO₂ is natural — from volcanic activity, animal respiration, forest decay, and ocean release. However, the remaining 3–5% is man-made, and it’s this portion that’s driving climate change. Why? Because the natural systems that absorb CO₂ — such as forests and oceans — can no longer keep up with the rate of human emissions.

This includes emissions from:

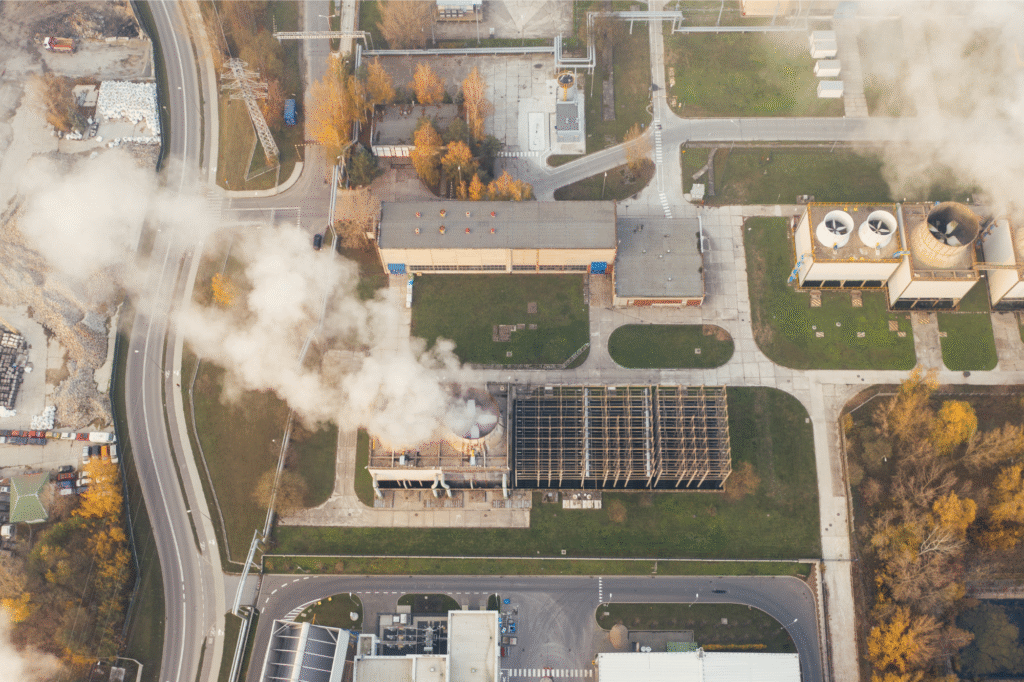

- Industrial gas production

- Fossil fuel combustion

- Transport and refrigeration gases

- Waste from consumables like short-life filters and gas system parts

How the Drinks Industry Contributes

The beverage sector uses carbon dioxide heavily — not just in the product itself, but in every step of production and service:

- Carbonating drinks like beer, cider, soda, and sparkling water

- Dispensing beverages under pressure in bars and restaurants

- Purifying and filtering CO₂ for food-grade use

- Replacing filters and venting unused gas, which adds to emissions and waste

Each time a filter is changed, or a gas cylinder is discarded, more carbon is released — through manufacturing, transport, and disposal. This is where operational choices start to influence atmospheric CO₂ levels. Read more about what a polishing filter is here.

Connecting This Back to Sure Purity

Sure Purity helps tackle this issue by extending the life of gas filtration equipment. Our filtration systems:

- Last 12 months, not 6 — halving solid waste

- Require fewer replacements — lowering transport and material emissions

- Ensure cleaner CO₂ at the point of use — so less gas is wasted, and more ends up in the glass

- Help beverage producers align with carbon reporting goals without major system overhauls

Reducing how much CO₂ your business contributes is just one way to respond to rising global levels. It starts with understanding where that CO₂ comes from — and choosing equipment that supports a lower-carbon future.

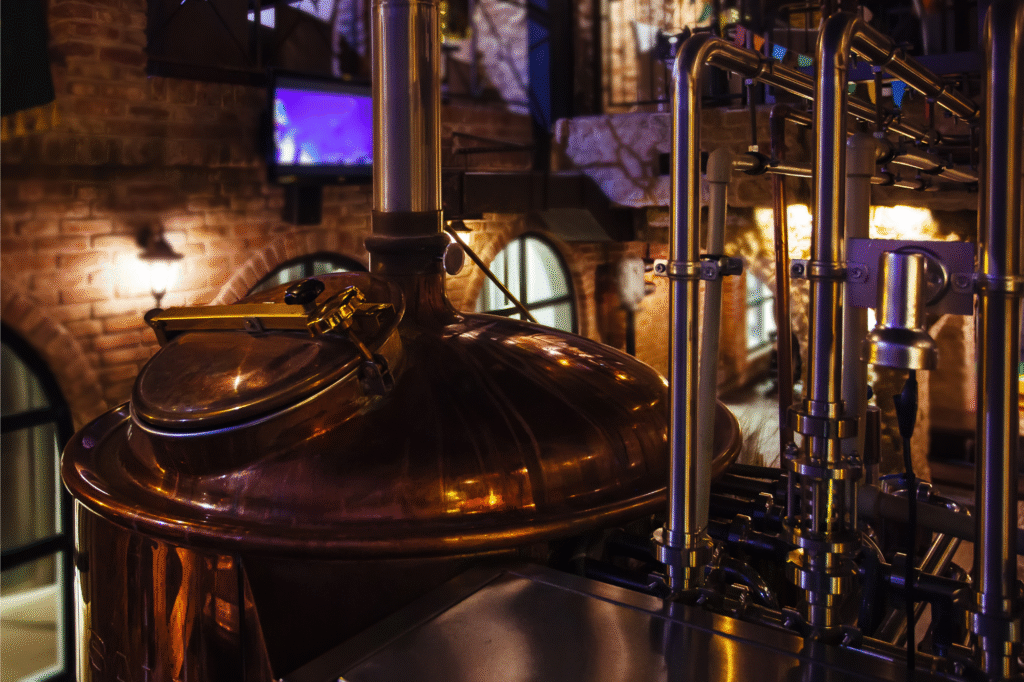

CO₂ in Beverage Production: Usage, Waste & Efficiency Risks

Carbon dioxide is essential to the drinks industry. It adds fizz, protects freshness, and ensures beer, cider, and soft drinks are dispensed with the right pressure and taste. But if not managed correctly, CO₂ usage can become a major source of waste. Both environmentally and financially.

Where CO₂ Is Used in the Drinks Industry

In beverage production and service, CO₂ is involved in several key stages:

- Carbonation – Injected during production to add sparkle to soft drinks, beer, and sparkling water

- Pressurisation – Used in kegs and dispense systems to push drinks from container to tap

- Packaging – Helps maintain shelf life and reduces oxygen exposure during bottling or canning

- Line purging – Used to clean or pressurise lines and tanks before use

Each use is necessary — but without the right equipment, gas can be wasted at every stage.

Common CO₂ Waste Points in Beverage Systems

CO₂ waste isn’t always visible. But even minor inefficiencies can lead to large losses over time:

- Gas leaks from fittings, valves, or regulators

- Over-carbonation resulting in vented excess gas

- Low-grade or contaminated CO₂ requiring repurification or venting

- Frequent filter replacements, which create solid waste and disrupt system efficiency

- Improper storage or handling of CO₂ cylinders

In bars, breweries, and bottling plants, these issues lead to unnecessary emissions — and higher operational costs.

Efficiency Matters: It’s Not Just About the Gas

Inefficient CO₂ use means more than just lost gas. It also means:

- More frequent deliveries of new cylinders

- More filters replaced, adding to landfill

- Greater energy usage during venting, purification, or cooling

- Poorer customer experience if carbonation or dispense pressure is off

- Less compliance with environmental reporting and carbon audits

For hospitality and beverage brands striving to meet environmental targets, CO₂ management is no longer a background concern — it’s a performance metric.

Sure Purity’s Solution to Efficiency Risk

Sure Purity offers high-performance filtration systems that reduce CO₂ loss and eliminate unnecessary waste:

- Longer-lasting filters (like our carboguard or carboguard mini) = fewer changeouts and less solid waste

- Point-of-use filtration = prevents taint, protects dispense quality, and reduces gas loss

- Clean CO₂ = fewer maintenance issues, better product taste, and lower emissions

By improving CO₂ quality and efficiency, drinks producers and retailers can cut costs, reduce environmental impact, and support more consistent beverage quality across every pour.

Sure Purity’s Filtration Systems: Designed to Reduce Waste

At Sure Purity, we believe sustainability starts with smarter system design. Our filtration products are engineered not just for performance, but for long-term environmental benefit — helping the drinks industry reduce waste and improve gas efficiency at every stage.

The Problem with Traditional CO₂ Filtration

Many beverage gas systems rely on outdated filtration methods. These often require:

- Frequent filter changes — sometimes monthly or quarterly

- Disposable filter media that contributes to solid waste

- Over-purification or unnecessary venting to remove impurities

- Non-targeted filtration that fails to remove key contaminants like benzene, sulphur, and moisture

This approach increases landfill, disrupts operations, and adds to a business’s carbon footprint. Over time, it’s both environmentally and financially unsustainable.

Sure Purity’s Cleaner, Longer-Lasting Filters

Sure Purity’s filters last up to 12 months, compared to the standard 3–6 months offered by many alternatives. That means:

- 50% less solid waste per year

- Fewer service visits and lower transport emissions

- Reduced downtime for replacements

- Lower total carbon footprint for gas filtration

- Better protection for beverage quality

Whether used in bottling plants, brewery dispense systems, or hospitality venues, our filters are built to support long-term, low-waste operations.

Zero-Waste CO₂ Filtration That Works Harder

Our filtration systems remove harmful contaminants without chemical media or waste-heavy processing. Each Sure Purity filter:

- Targets key impurities like benzene, H₂S, hydrocarbons, and water vapour

- Maintains high gas flow rates without compromising filtration efficiency

- Works in line at the point of dispense, reducing system-wide contamination risks

- Meets or exceeds food-grade CO₂ standards set by bodies like EIGA and ISBT

Cleaner gas means fewer taints, better taste, and less energy wasted on post-contamination clean-ups.

Built for the Drinks Industry, Backed by Industry Experts

Our products are trusted by:

- Breweries looking to preserve craft beer flavour

- Hospitality venues needing consistent pours and low maintenance

- Bottling plants aiming to streamline production and meet ESG goals

With a deep understanding of beverage gas systems, Sure Purity supports operators in reducing waste without sacrificing quality — making it easier to meet both technical standards and sustainability targets.

Reducing Carbon Footprint Through Smarter Gas Handling

Controlling carbon emissions isn’t just a global challenge — it’s a practical, everyday opportunity for businesses across the drinks industry. From gas sourcing to system efficiency, every step in your CO₂ handling process impacts your carbon footprint. That’s where smarter gas management, supported by Sure Purity technology, makes a real difference. You can read more about how to keep co2 levels down in the drinks industry in our dedicated guide.

How CO₂ Handling Affects Your Carbon Emissions

Many drinks producers, breweries, and hospitality businesses unknowingly contribute to excess carbon emissions through inefficient gas handling. Common issues include:

- Overuse of gas due to leaks or poor pressure control

- High-frequency filter replacements leading to transport emissions and disposal waste

- Low-grade CO₂ requiring repurification or venting

- Unnecessary energy usage in refrigeration or cryogenic CO₂ storage

These operational oversights don’t just increase environmental impact — they raise costs and reduce system reliability.

Efficiency as a Sustainability Tool

Reducing your business’s carbon footprint doesn’t always require large-scale investment or operational overhaul. Often, the biggest wins come from small changes to how gas is filtered and used:

- Using fewer filters per year cuts manufacturing, packaging, and logistics emissions

- High-purity gas reduces spoilage and the need for reprocessing or waste disposal

- Inline filtration prevents contamination at point-of-use, eliminating the need for post-pour purging or corrective flushing

- Well-regulated CO₂ flow ensures consistent carbonation with minimal waste

Sure Purity filters are designed with all of this in mind — offering a clean, consistent flow with lower environmental impact.

Real Results: Halving Solid Waste with Fewer Filter Changes

By extending the lifespan of our filters to 12 months, we help our customers halve their solid filter waste. That means:

- 6 filters per year instead of 12

- Less packaging

- Fewer deliveries

- Lower disposal costs

- Reduced carbon emissions across the product life cycle

This isn’t just a maintenance benefit — it’s a measurable step toward your ESG and carbon reporting goals.

Aligning Technical Operations with Sustainability Goals

Many organisations in the beverage sector are now expected to report on their environmental performance. Whether you’re pursuing net zero targets, working toward B Corp status, or simply aiming to reduce waste, gas handling is a key area of opportunity.

Sure Purity helps bridge the gap between technical operations and environmental responsibility. Our systems offer a practical, low-effort way to reduce emissions, align with sustainability frameworks, and support your long-term CSR commitments.

Clean CO₂ Is Part of a Cleaner Future

The concentration of CO₂ in our atmosphere is a growing global concern — but real progress starts with local, practical action. This means rethinking how carbon dioxide is used in the drinks industry, managed, and purified every day.

CO₂ is essential for carbonation, packaging, and product quality. But wasteful handling, frequent filter replacements, and inefficient systems all contribute to unnecessary emissions. By upgrading your gas filtration setup, you can reduce your environmental impact without compromising performance.

At Sure Purity, our mission is to support a more sustainable drinks industry — one that prioritises both product integrity and environmental responsibility. Our long-life, zero-waste filters are already helping breweries, hospitality businesses, and beverage producers:

- Cut solid waste by 50%

- Reduce the carbon footprint of their CO₂ systems

- Ensure food-grade gas purity for every pour

Cleaner CO₂ means better beer, less waste, and a healthier planet. And it starts with the decisions made behind the bar, in the cellar, or on the production line.

Ready to take a smarter, cleaner approach to CO₂ in your business?

Explore our full range of Sure Purity filtration products or contact our team for tailored advice on building a more sustainable gas system.