- Blaydon on Tyne

- [email protected]

- 0191 9330630

- Blaydon on Tyne

- [email protected]

- 0191 9330630

- Blaydon on Tyne

- [email protected]

- 0191 9330630

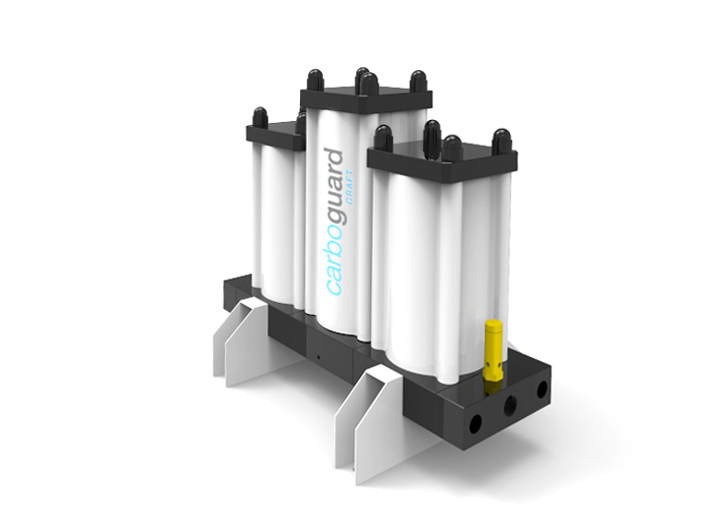

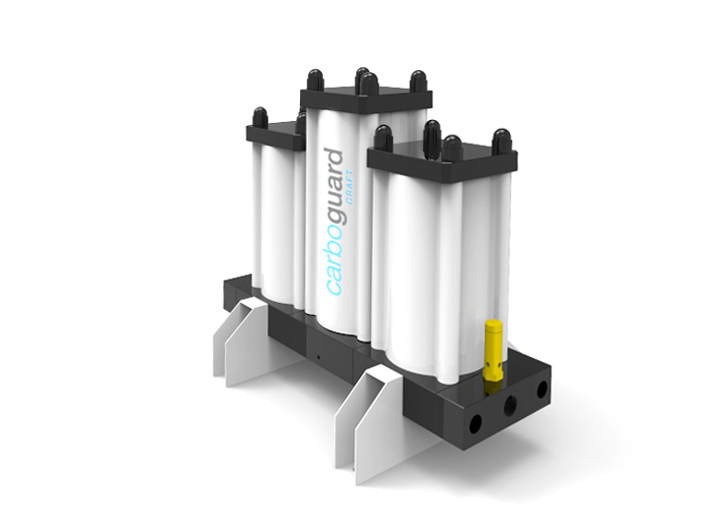

In the competitive world of craft brewing, quality isn’t just important—it’s everything. Your customers expect perfection in every pint, and even the smallest contamination can compromise your brand’s reputation. That’s where CarboGuard Craft steps in as your final line of defence.

Carbon dioxide isn’t just a by-product—it’s your beverage’s fifth ingredient, right alongside water, malts, hops, and yeast. Yet whilst you carefully select your premium ingredients, how much attention do you pay to the quality of your CO₂?

Industrial CO₂ can contain trace impurities from various sources including volatile hydrocarbons, hydrogen sulphide, and moisture. These contaminants risk off-flavours, unpleasant aromas, and quality incidents that could damage consumer confidence in your brand.

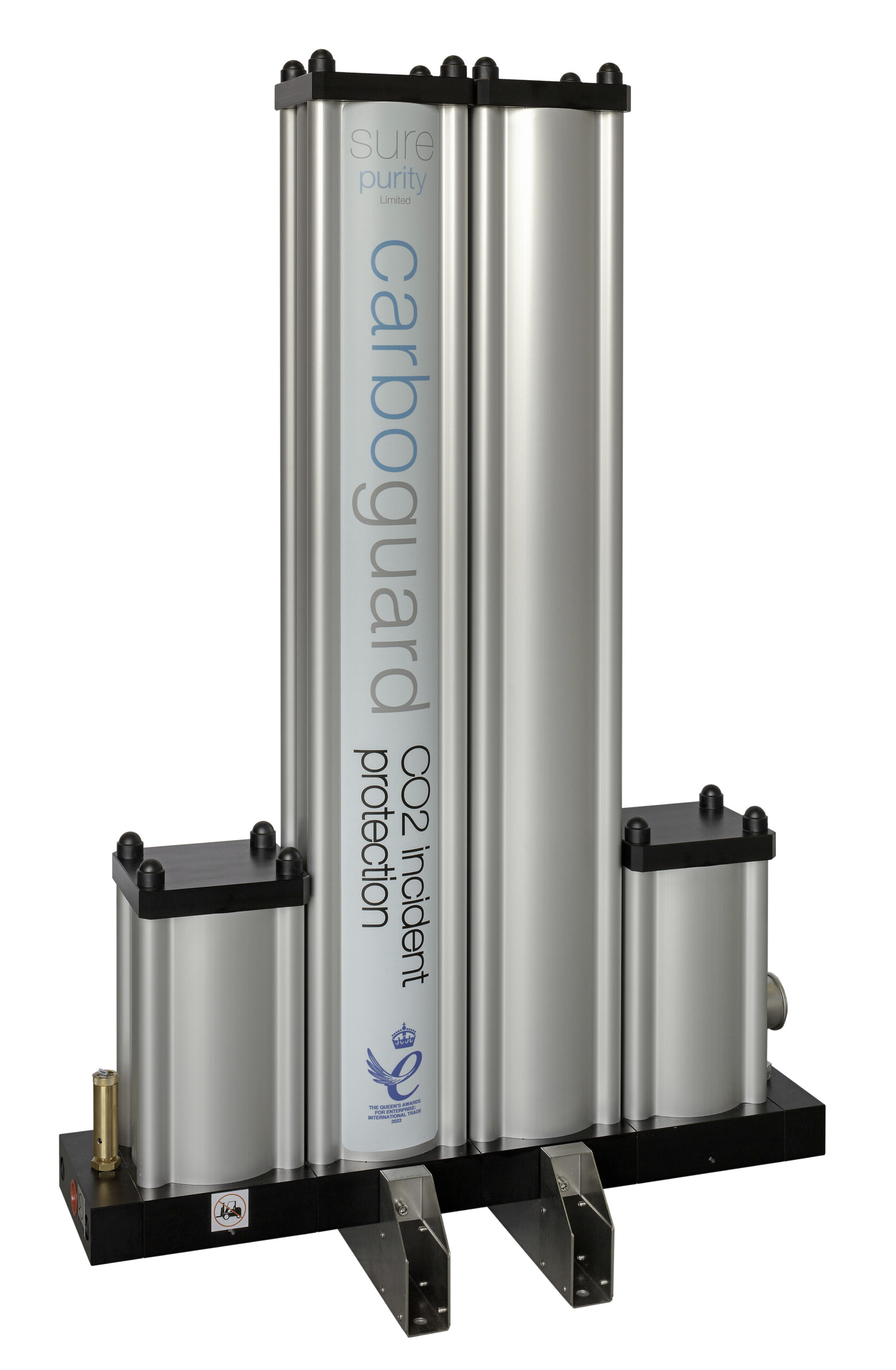

Multi-Stage Protection That Actually Works

CarboGuard CRAFT utilises our proprietary snow storm filling technique with advanced adsorption technologies, delivering:

As standard (with optional 6th stage for microbiological protection)

Up to 10x greater than ISBT guidelines

To protect against trace impurities

Required vs. competitors

For minimal downtime

An optional 6th stage provides protection against microbiological cross-contamination in breweries orother sources where this is deemed a risk.

Unlike generic filtration systems, CarboGuard Craft is specifically designed for the unique challenges of craft brewing:

start small and expand as you grow

fits into space-constrained breweries

with annual service kits

CarboGuard has undergone rigorous validation by internationally recognised laboratories accredited to ISO17025:2015. Testing included challenging the system with a comprehensive range of impurities, proving its superior ability to reduce Carbonyl Sulphide (COS) levels well below ISBT limits.

Materials verified to comply with CFR.175 & 21CFR.177

by an internationally recognized laboratory accredited to ISO17025:2015

as a processing aid for the polishing of CO₂ for use in food and beverage manufacturing

including The Coca-Cola Company and PepsiCo

EN 12873-4 2006-6 CEN/TC 164 certified

For use in food and beverage manufacturing

Trusted by major global beverage companies

across all cartridges

for optimal performance

averaging just 30 minutes maintenance annually

required compared to loose-fill alternatives

to dispose of

through efficient design

over equipment lifetime