How to Test Gas Quality in Beverage Systems

In beverage production, gas quality has a direct impact on taste, safety, and reputation. Every pint, bottle, or glass depends on one often-overlooked ingredient – carbon dioxide. CO₂ is essential for carbonation and dispense pressure, but its quality can vary more than many producers realise. Even gas labelled as “beverage-grade” can contain trace impurities that […]

Common Draught Beer Problems Caused by CO₂

Most beer quality complaints start with CO₂, not the brew itself. The gas that carbonates and dispenses every pint is also one of the most overlooked sources of quality problems in bars and breweries. CO₂ is vital for maintaining carbonation, pressure, and mouthfeel. Yet, when its quality slips, even slightly, it can ruin taste, aroma, […]

Understanding How Gas Affects Draught Beer

Gas drives every pint you pour. It does more than push beer to the tap. It shapes flavour, mouthfeel, and foam. Most dispense issues trace back to gas, not the beer. Small changes in gas purity or pressure cause big problems. Flat pours. Harsh aromas. Foam that collapses too fast. Customers notice immediately. Two gases […]

Sure Purity Is Exhibiting at Drinktec 2025

Join Sure Purity at Drinktec 2025 (15–19 September, Messe München) where we’ll be showcasing our Carboguard™ CO₂ filtration systems and hosting daily live demonstrations. Plan Your Visit Hall B4, Stand B4-10115–19 September 2025Messe München, Germany If you’re a potential prospect and would like free tickets to Drinktec – please get in touch with us. Why Visit Sure Purity at Drinktec? […]

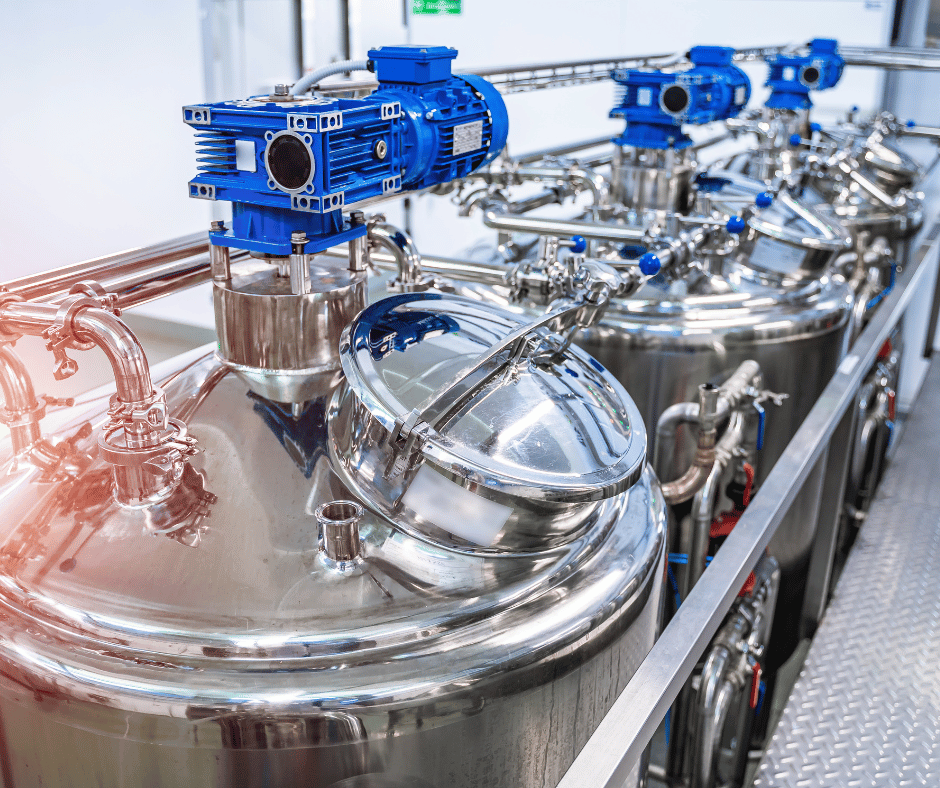

How to Force Carbonate Beer: Methods, Pressure, and Gas Filtration Explained

You’ve brewed the perfect batch—balanced, flavourful, and ready to serve. But there’s a catch: it needs to be carbonated fast. Whether you’re preparing for a product launch, restocking taps, or speeding up production, waiting weeks for natural carbonation simply isn’t an option. That’s where force carbonation comes in. This method allows brewers to add precise […]

At What Temperature Does Beer Freeze? Causes, Effects & How to Prevent It

You’re mid-service on a busy Friday night, and suddenly, one of the taps stops pouring. The line has frozen. It’s a frustrating moment—beer wasted, customers waiting, and revenue on hold. But can beer really freeze? The answer is yes. While beer freezes at a lower temperature than water due to its alcohol content, it’s not […]

Proper Beer Serving Temperatures: A Guide to Getting Every Pint Just Right

Picture this: a pint poured ice-cold, looking perfect — but the first sip tastes of nothing. The flavour’s muted. Now imagine the opposite: a warm pint that tastes flat, fizzy in the wrong way, and lacks any crispness. Both are caused by one simple issue — serving beer at the wrong temperature. Temperature plays a […]

Ultimate Guide to Beer Line Cleaning for Beverage Professionals

Picture the scene: a customer sends their pint back, complaining it tastes sour or musty. It’s not the keg. It’s not the glass. It’s the lines. Dirty beer lines are one of the biggest causes of flavour taint, foaming issues, and customer dissatisfaction in pubs and bars. This isn’t just about taste—it’s about hygiene and […]

How Long Does Draught Beer Last? Tips for Freshness & Shelf Life

It starts with a returned pint. The customer leans over the bar, eyebrows raised. “This doesn’t taste right.” The bartender takes a sip, frowns, and nods. Another pint poured down the drain. Another dent in your margins—and possibly your reputation. Every venue serving draught beer knows this moment. And often, it’s not the beer’s brand, […]

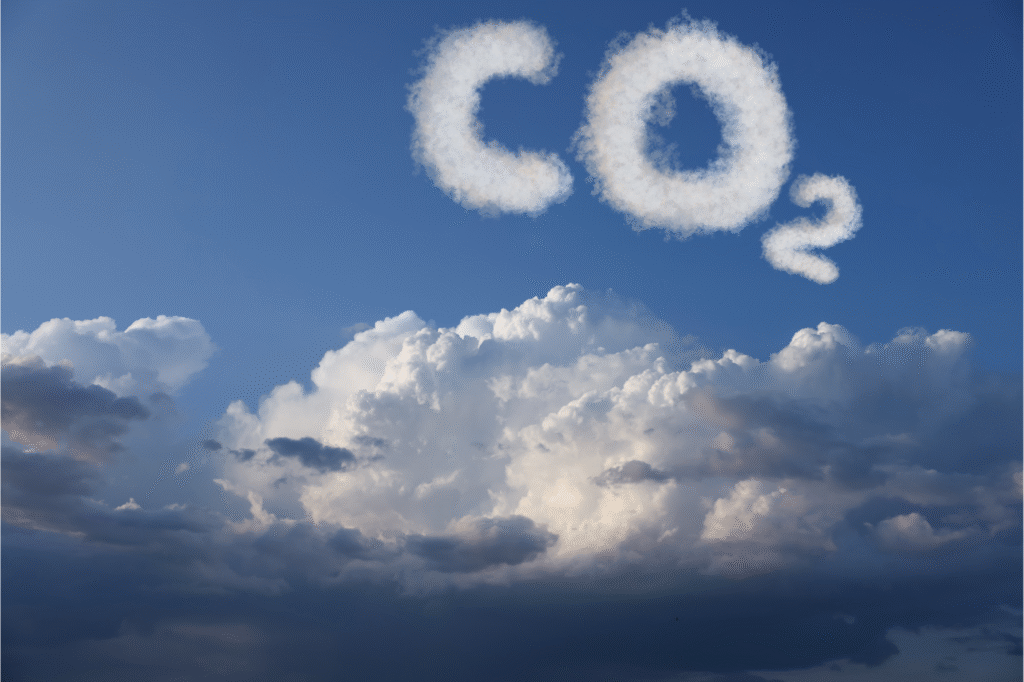

How Much CO₂ Is in the Atmosphere

How much CO₂ is in the atmosphere? Today, atmospheric carbon dioxide levels sit at around 420 parts per million — just 0.04% of our air. But this small percentage plays a big role in climate change, global warming, and industry accountability. For the drinks and hospitality industry, carbon dioxide is more than just a greenhouse […]