When draught beer tastes dull, pours flat, or loses its head too quickly, dirty beer lines are often blamed first. In many cases, that’s a fair assumption. Poor line hygiene can ruin flavour, damage foam, and undo the work of the brewer. But it is rarely the whole story.

Even venues that clean their beer lines on schedule can struggle with inconsistent pours, off-flavours, or weak carbonation. The reason is simple. Beer quality depends on more than the liquid pathway alone. Gas quality, pressure, and overall dispense hygiene all play a role.

Beer line hygiene remains essential. Without it, no draught system will perform well. Yet cleaning alone does not always solve every problem. Some faults persist because contamination or instability enters the system elsewhere.

This guide explains how to clean draught beer lines correctly, why the process matters, and what best practice really looks like. It also shows why a complete hygiene strategy must consider both beer lines and the gas that drives the pour.

Why Cleaning Draught Beer Lines Matters – And What It Improves

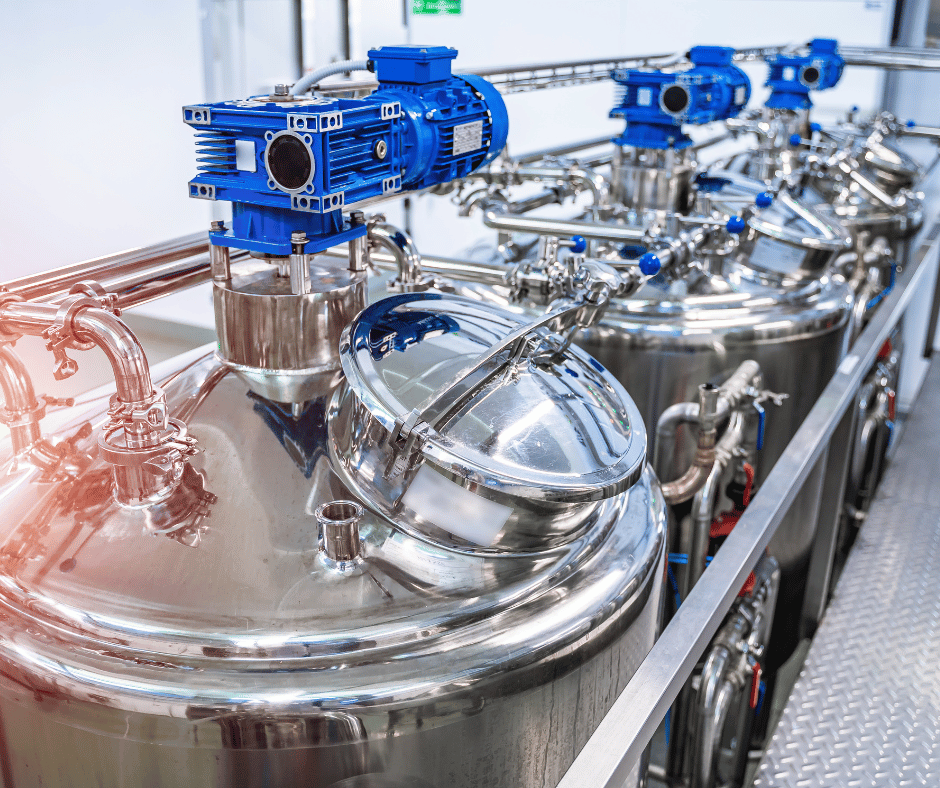

Draught beer lines sit at the centre of the dispense system. Every pint passes through them, carrying yeast, protein, and sugars that naturally build up over time. If lines are not cleaned properly, residue forms on the inner surfaces and creates biofilm. Once this happens, beer quality begins to decline.

Dirty lines affect beer in several ways. Flavour becomes muted or slightly sour. Aroma loses its freshness. Foam collapses quickly, leaving the beer looking flat and lifeless. In more severe cases, the beer can develop unpleasant off-notes that customers notice immediately.

These problems often appear gradually. A beer that tastes clean and bright one week can taste dull the next, even though nothing has changed at the brewery or in the cellar. This slow decline is why line hygiene is so important. Without regular cleaning, issues build up silently until complaints start coming in.

When draught beer lines are cleaned properly and on schedule, the improvement is clear:

- Better taste and aroma

Clean lines allow the beer’s intended flavour profile to come through without interference. - Improved foam retention

Removing residue helps foam proteins form and hold their structure. - More consistent pours

Beer flows more predictably from tap to glass. - Reduced waste

Fewer rejected pints and fewer “fixes” behind the bar. - Longer equipment lifespan

Clean lines reduce stress on couplers, taps, and seals. - A better customer experience

Every pint looks and tastes as it should.

Yet even with perfectly cleaned lines, some venues still struggle with flat or inconsistent beer. When this happens, the issue often lies beyond the beer line itself. The next step is to look at the gas that drives the pour.

The Draught Beer Line Cleaning Process Explained

Cleaning draught beer lines correctly is about more than running a solution through the system. It requires the right method, the right frequency, and proper verification. When any part of the process is rushed or skipped, residue remains behind and quality issues return quickly.

Step-by-Step Line Cleaning Process

Most draught systems should be cleaned on a weekly or fortnightly schedule, depending on throughput, beer type, and system length. High-volume venues and craft beers with higher protein content often need more frequent cleaning.

A typical cleaning process includes:

- Isolating the system

Disconnect kegs and ensure the system is safe to clean. - Applying the cleaning method

Chemical cleaning uses approved beer line cleaning chemicals to break down yeast, protein, and sugar deposits. Mechanical cleaning adds a physical element, such as sponge balls or brushes, to scrub stubborn biofilm from the line walls. Many systems benefit from a combination of both. - Allowing proper contact time

Cleaning solutions must stay in the lines long enough to work. Rushing this step reduces effectiveness and leaves residue behind. - Thorough rinsing

Lines must be flushed completely with clean water. Any chemical left in the system will affect flavour and safety. - Verification and reconnection

The system should be checked for clarity, odour, and flow before reconnecting kegs. A clean system should have no lingering smells and should pour smoothly.

Following each step consistently prevents buildup and keeps beer tasting as intended.

Common Mistakes During Line Cleaning

Many draught issues persist because of small but repeated mistakes during cleaning. The most common include:

- Infrequent cleaning

Stretching cleaning intervals allows biofilm to establish and become harder to remove. - Incorrect chemical strength

Solutions that are too weak fail to break down residue. Solutions that are too strong risk damaging lines and fittings. - Poor flushing

Incomplete rinsing leaves chemical traces that affect flavour and foam. - Ignoring couplers and taps

These components collect residue just as quickly as lines and must be cleaned at the same time.

Even well-intentioned cleaning routines fall short when these details are missed. This is why some venues continue to experience quality problems despite regular line cleaning.

The Role of CO₂ Quality in Draught Beer Performance

Beer lines deliver the liquid, but CO₂ controls how that beer behaves in the glass. It does far more than push beer from keg to tap. CO₂ becomes part of the drink itself, shaping how it tastes, feels, and looks when served.

How CO₂ Interacts with Beer

CO₂ influences several key elements of draught beer quality:

- Carbonation

CO₂ dissolves into the beer under pressure, creating fizz and lift. Stable carbonation depends on clean gas and consistent pressure. - Mouthfeel

The amount and quality of CO₂ affect how smooth or sharp a beer feels on the palate. Poor gas quality can make beer draught beer feel harsh or flat. - Aroma release

Rising CO₂ bubbles carry aroma compounds to the surface. If carbonation is weak or unstable, aroma expression suffers. - Foam stability

Clean CO₂ supports tight bubbles and lasting head formation. Impurities disrupt foam proteins and cause the head to collapse quickly.

When CO₂ is clean and consistent, these elements work together to deliver the beer as intended.

How Contaminated CO₂ Undermines Clean Lines

Even with perfectly cleaned beer lines, contaminated CO₂ can undo the results. Gas quality issues often show up as:

- Flat beer despite correct pressure

Impurities interfere with CO₂ absorption, causing carbonation to drop faster than expected. - Chemical or sulphurous aromas

Trace compounds such as carbonyl sulphide or hydrogen sulphide can add burnt or sulphur notes to the beer. - Inconsistent pours

Unstable gas leads to fluctuating carbonation, producing different results from one pint to the next.

These problems are often blamed on line hygiene or pressure settings, when the real issue sits in the gas supply. This is why CO₂ cleaning matters just as much as beer line cleaning.

How CO₂ Cleaning Complements Beer Line Hygiene

Cleaning beer lines removes residue from the liquid pathway. CO₂ cleaning protects the gas pathway. Together, they form a complete dispense hygiene strategy.

What Is CO₂ Polishing?

CO₂ polishing is the process of removing trace impurities from carbon dioxide before it enters the dispense system. It focuses on cleaning the gas itself, not the cylinder or the equipment around it.

Polishing targets contaminants that standard filtration and supplier certification can miss. These include sulphur compounds, hydrocarbons, moisture, and other trace impurities that affect flavour and carbonation stability.

Carboguard Mini for Complete Dispense Hygiene

Carboguard Mini is designed to sit downstream of line cleaning, acting as the final protection layer before CO₂ reaches the beer. It removes impurities picked up during production, transport, or cylinder handling.

Carboguard Mini removes:

- Carbonyl sulphide (COS)

- Hydrogen sulphide (H₂S)

- Hydrocarbons

- Moisture

By polishing CO₂ at the point of use, it delivers clear benefits:

- Cleaner flavour and aroma

No chemical or sulphurous interference. - More stable carbonation

CO₂ dissolves and holds more consistently. - Better foam retention

Tighter bubbles and longer-lasting heads. - Fewer complaints after cleaning cycles

Quality stays consistent, rather than drifting between cleans.

When beer lines and CO₂ are both clean, draught beer performs the way it should. Every pour becomes more predictable, more consistent, and more enjoyable for the customer.

Best Practices for Long-Term Draught Beer Quality

Consistent draught beer quality does not come from one-off fixes. It comes from routines that protect both the liquid and gas pathways over time. When best practices are followed, beer tastes better, pours more reliably, and creates fewer problems behind the bar.

Maintain a Cleaning Schedule

Regular beer line cleaning is non-negotiable. Most draught systems should be cleaned every week or fortnight, depending on volume, beer style, and system design. High-protein or unfiltered beers often require more frequent cleaning.

Sticking to a schedule prevents residue and biofilm from forming. It also makes cleaning easier, as buildup never has time to harden. Documenting cleaning dates helps ensure nothing is missed and keeps quality consistent across shifts.

Monitor Gas and Pressure

Gas pressure must remain stable for carbonation to hold correctly. Sudden changes lead to flat or foamy pours, even in clean systems.

Best practice includes:

- Checking regulators regularly

- Avoiding unnecessary pressure adjustments

- Using the correct gas blend for each beer style

Stable pressure allows CO₂ to dissolve properly and supports consistent mouthfeel, aroma, and foam.

Include CO₂ Quality in Your Hygiene Routine

CO₂ quality should be treated with the same importance as beer line hygiene. Gas enters the drink directly, so any impurity affects the final pour.

A complete hygiene routine includes:

- Periodic gas quality checks

- Polishing CO₂ to remove trace contaminants

- Treating gas as an ingredient, not just a utility

CO₂ polishing ensures that cleaning results last longer, rather than fading between maintenance cycles.

Final Thoughts

Clean beer lines are essential for draught quality, but they are only part of the picture. When problems persist after cleaning, CO₂ quality is often the missing piece.

True dispense hygiene includes both liquid and gas pathways. By cleaning beer lines and polishing CO₂, venues protect flavour, carbonation, foam stability, and consistency across every pour.

Discover how Sure Purity’s Carboguard completes your draught hygiene strategy by delivering clean, polished CO₂ to every pour.